Anyone who’s spent a full shift on their feet knows the feeling. Standing on hard concrete all day is just plain draining. But industrial anti-fatigue mats are more than just a bit of cushion underfoot; they're a critical ergonomic tool designed to fight fatigue and boost productivity. This guide provides actionable steps to help you select, install, and maintain the right mats to protect your team and improve your operations.

Why Your Workplace Needs Anti-Fatigue Mats

Think about driving a car without any suspension. You’d feel every single crack and bump in the road, making for a jarring, uncomfortable, and physically exhausting ride. That’s exactly what standing on a hard floor like concrete or tile does to the human body. The unforgiving surface sends tiny shockwaves shooting up through the feet, legs, and even the spine, causing nagging pain and sapping energy.

This is where industrial anti-fatigue mats come into play. They act as a high-performance suspension system for your workforce, absorbing the impact and providing a more forgiving surface.

Actionable Insight: A quality anti-fatigue mat is a piece of strategic equipment. It's engineered to absorb the constant impact of standing, reducing the daily wear and tear on your employees' bodies. This isn't a comfort item; it's a productivity tool.

From Static Pain to Dynamic Comfort

When someone stands still on a rigid floor, their leg muscles tense up and become static. This muscle constriction is bad news—it slows down blood flow, which quickly leads to pain and a noticeable drop in concentration. Industrial anti-fatigue mats are specifically built to solve this problem. Their cushioned, yet supportive, surface encourages continuous, subtle micro-movements in the leg and calf muscles.

These tiny, almost unconscious movements are the key. They act like a natural pump, promoting healthy blood circulation and stopping blood from pooling in the lower legs. The direct benefit is a massive reduction in physical strain and mental fatigue.

Real-World Example: Improving Assembly Line Focus

- The Problem: A busy assembly line where technicians stand for an eight-hour shift inspecting small components. Without proper matting, by mid-afternoon, they suffer from back pain and sore feet. This leads to more unscheduled breaks and a higher number of mistakes slipping through quality control.

- The Action: The facility manager installs durable industrial anti-fatigue mats at every workstation.

- The Benefit: The difference is night and day. Employees report feeling significantly less tired, and QC data shows a 15% decrease in assembly errors. The matting didn't just make the floor feel softer; it created an environment where the team could stay energized and focused.

This illustrates the direct link between employee well-being and operational success. By investing in the right ergonomic tools, you can achieve measurable improvements in:

- Employee Health: Fewer complaints about back, leg, and foot pain.

- Team Productivity: Higher concentration levels and a reduction in costly errors.

- Workplace Morale: A powerful signal that you value your team's health and safety.

To get a better handle on the science behind this, you can dive into our detailed guide on what are anti-fatigue mats and how they really work. Taking this proactive approach to workplace ergonomics is a cornerstone of any safe and productive industrial environment.

The Science Behind How Anti Fatigue Mats Work

Ever wondered what’s actually happening under a worker’s feet when they stand on an industrial anti-fatigue mat? It’s more than just soft cushioning; it's a clever piece of ergonomic science designed to work with the human body. Understanding how they work shows exactly why these mats are a game-changer for workplace health and safety.

When someone stands on a hard, unyielding surface like concrete, their leg muscles are forced to lock up just to keep them upright. This constant, static muscle contraction squeezes blood vessels, disrupting circulation. Blood starts to pool in the lower body, muscles are starved of oxygen, and that all-too-familiar feeling of deep fatigue and pain sets in.

Activating Dynamic Ergonomics

This is where the genius of an anti-fatigue mat comes into play. Its cushioned surface is engineered to be just unstable enough to introduce something called dynamic ergonomics. This subtle instability forces the body to make constant, tiny adjustments to maintain balance.

These tiny shifts, known as micro-movements, are the secret to fighting off muscle fatigue. They make the calf and leg muscles rhythmically contract and relax in a way you don't even notice. This gentle muscle activity essentially acts like a pump, pushing blood back up toward the heart instead of letting it pool in the legs.

Actionable Takeaway: An anti-fatigue mat isn't just a cushion; it's an active surface. It turns draining, static standing into a dynamic activity that boosts healthy circulation and takes a huge amount of physical strain off the body, directly leading to increased alertness and reduced pain.

Real-World Scenario: A Warehouse ROI Analysis

- The Problem: A large distribution warehouse manager notices a big drop in picking accuracy in the last two hours of every shift, coupled with a high number of complaints about sore legs and backs.

- The Action: The manager runs a trial, installing high-quality industrial anti fatigue mats at all fixed packing and sorting stations. They track the results over three months.

-

The Benefit: The results are clear and measurable.

- Complaint Reduction: End-of-day fatigue complaints dropped by over 40%.

- Accuracy Improvement: Picking and packing errors in the final hours of shifts fell by a measurable 18%.

- Morale Boost: Employees mentioned the mats as a major improvement to their work environment.

This example spells it out. By tackling static standing, the mats didn't just ease aches and pains. They directly created a more alert, focused, and productive team. The investment in ergonomic matting quickly paid for itself through fewer mistakes and better efficiency.

Good ergonomic support has a powerful ripple effect. If you want to dive deeper into the specific health impacts, our article exploring how anti-fatigue mats and your health are connected is a great resource. The science is clear: better blood flow means less fatigue, which translates directly to a safer, more effective workplace.

How to Choose the Right Mat Material for Your Environment

Picking the right industrial anti-fatigue mat isn't like choosing an office rug. The stakes are much higher. The wrong choice can wear out in weeks, create new safety hazards, and fail to provide any ergonomic benefits. Making the smart call starts with understanding the core materials and matching them to your specific workplace.

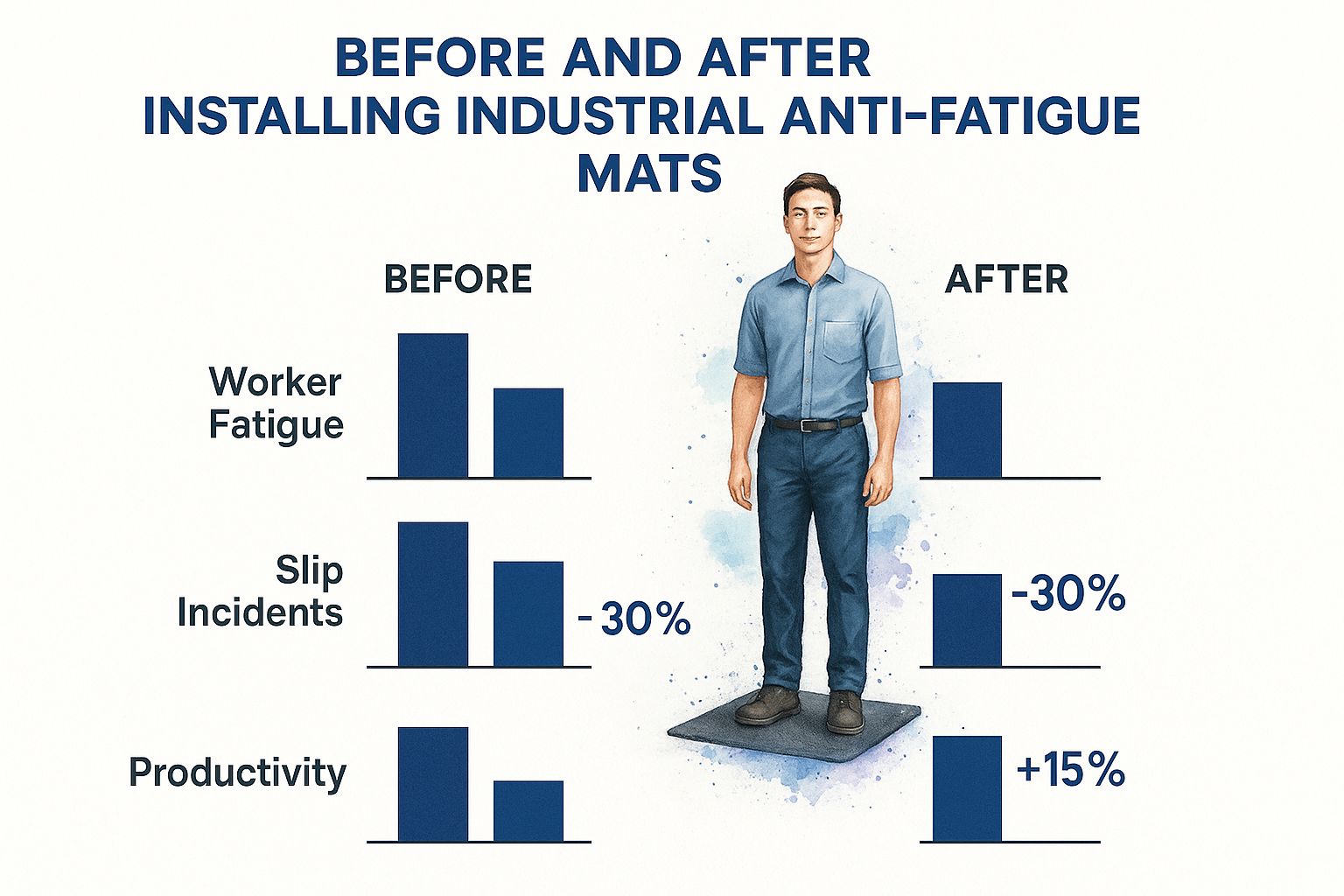

Think of it like choosing tires for a truck. You wouldn't put street tires on a rig that plows through mud; you’d get specialized tires built for that exact job. Similarly, the material of your anti-fatigue mat must be tough enough for your work environment. The data below shows the real improvements businesses see after installing the correct industrial anti-fatigue mats—significant drops in fatigue and slips, plus a boost in productivity.

As you can see, the right matting is a powerful tool that directly impacts everything from safety records to output.

Industrial Anti Fatigue Mat Material Comparison

Choosing the best material comes down to a trade-off between durability, comfort, and resistance to your environment. A mat that’s perfect for a dry assembly line will fail miserably in a greasy machine shop. This table breaks down the most common materials to help you pinpoint the best option.

| Material Type | Best For | Durability | Chemical Resistance | Comfort Level |

|---|---|---|---|---|

| Rubber | Oily, greasy, and wet industrial areas | Excellent | Very Good | Good |

| PVC (Vinyl) | Dry environments, general purpose use | Good | Moderate | Good |

| Polyurethane | High-traffic dry areas, maximum comfort | Excellent | Moderate | Excellent |

The goal is to find the sweet spot where the mat’s properties align with your daily operational realities. Let’s dig deeper into what makes each material tick.

Rubber: The Durable Workhorse

Rubber is one of the most reliable materials for industrial anti-fatigue mats due to its incredible durability and resistance. Think of it as the all-terrain option for the most challenging environments. Its main strength is its ability to stand up to harsh conditions, but not all rubber is created equal. Nitrile rubber, for instance, is a blend engineered to be highly resistant to the oils and greases that would make other materials swell and fall apart.

- Real-World Example: In an auto repair shop, mechanics deal with engine oil and corrosive fluids. A standard PVC mat would become a swollen, slippery mess. A 100% nitrile rubber mat is the practical choice. It provides the cushioning needed to fight fatigue while its tough surface repels oils, ensuring it stays safe and effective for years.

PVC (Vinyl): The Versatile and Cost-Effective Choice

Polyvinyl Chloride (PVC or vinyl) strikes a great balance between comfort, durability, and cost, especially for dry work areas. Most of these mats feature a closed-cell PVC construction, where the mat is filled with countless tiny air bubbles, providing excellent cushioning. PVC mats are typically lighter than rubber and can come with features like antimicrobial properties, making them a go-to for certain clean-room or food service applications.

- Real-World Example: In a large food processing plant, hygiene is non-negotiable. A closed-cell PVC mat with antimicrobial properties is perfect. It stops bacteria from growing, is easy to clean, and gives workers the relief they need—helping the plant hit its hygiene targets without sacrificing employee well-being.

Polyurethane: The Premium Comfort Solution

When maximum comfort is the absolute priority, polyurethane is in a class of its own. It delivers "best-in-class" cushioning that dramatically reduces stress on feet, legs, and the lower back. While it’s often a more premium investment, its exceptional longevity and superior comfort can deliver a fantastic return. Polyurethane is also incredibly durable and resistant to abrasion, making it ideal for high-traffic dry areas.

Polyurethane mats offer resilience and comfort that other materials can't match. They are engineered to bounce back and keep their cushioning power for a very long time, even under constant, heavy use.

- Real-World Example: At an electronics assembly facility, workers stand at intricate soldering stations where focus is key. Any physical discomfort can lead to expensive mistakes. A high-density polyurethane industrial anti-fatigue mat is the ultimate solution. It provides the highest level of comfort, keeping technicians focused and pain-free, which directly translates to better quality control and fewer product defects.

The market for these materials is influenced by the growing focus on workplace wellness. While rubber remains dominant, polyurethane is gaining ground as companies prioritize superior cushioning. This trend is driven by a greater awareness of musculoskeletal disorders. For more on this, explore detailed matting industry trends at Fortune Business Insights.

Key Features to Consider Before You Buy

Once you’ve settled on the right material, it’s time to dig into the specific design features. These details directly impact a mat’s safety, performance, and longevity. Getting these features right is what separates a truly effective ergonomic tool from just another piece of flooring. Think of it like buying a car: you wouldn't drive it off the lot without checking the tires and brakes.

Actionable Tip #1: Prioritize Edges and Surfaces That Prevent Accidents

One of the most important safety features is the edge. A mat with a blunt, 90-degree edge is an accident waiting to happen. To prevent this, implement this simple "how-to" step:

- How-To: Always select mats with beveled or sloped edges. These tapered edges create a smooth ramp from the floor to the mat, allowing feet and carts to glide over easily. For maximum safety, choose mats with bright yellow or orange borders to make them impossible to miss.

The surface pattern is just as critical. A smooth mat can become dangerously slick. Match the surface to your needs:

- Diamond-Plate Pattern: The go-to surface for fantastic grip from every direction.

- Grit-Coated Surface: For constantly wet or oily areas, this offers aggressive, sandpaper-like traction.

- Drainage Holes: A must-have in workstations with heavy liquid use, allowing fluids to pass through and keep the surface dry.

Actionable Tip #2: Select the Correct Mat Thickness

A common misconception is that thicker is always better. A mat that's too soft can cause instability, forcing leg muscles to work overtime to stay balanced, which can ironically lead to more fatigue.

- How-To: For most industrial jobs, choose a 5/8-inch thickness. This provides the perfect blend of supportive cushioning and firm stability. If you have workstations with exceptionally long standing periods or need to support heavier workers, stepping up to a 7/8-inch mat is the right call.

The goal is ergonomic support, not just softness. A properly engineered mat provides a firm, stable base that yields just enough to encourage micro-movements and absorb shock, without causing instability.

Actionable Tip #3: Match Special Properties to Your Workstation

Finally, do a quick risk assessment of each workstation to pinpoint unique environmental challenges. This is how you deploy a specialized tool that solves a real problem.

- Real-World Example: An electronics plant struggled with high product defect rates. An audit revealed that static discharges from workers were frying sensitive microchips.

- The Action: They swapped standard flooring for specialized anti-static industrial anti-fatigue mats.

- The Benefit: The mats safely channeled static electricity away from the worker and electronics. Product damage from static vanished, delivering a massive return on investment.

Apply this same logic to your environment:

- Welding Areas: Demand mats with fire-retardant properties that can shrug off sparks and hot slag.

- Food Production: Require mats with antimicrobial additives to stop bacteria and mold growth.

- Chemical Plants: Need mats built from materials proven to resist specific chemical spills without degrading.

The Business Case for Ergonomic Matting

It's easy to see industrial anti-fatigue mats as a simple expense. That’s a shortsighted mistake. The smarter way to see them is for what they are: a high-return investment in your company’s bottom line. When you look at the numbers, a powerful business case snaps into focus. Putting your team’s well-being first isn't just "nice-to-have"—it's a competitive advantage that leads to dramatic cost reductions.

Slashing Costs Tied to Absenteeism and Injury

One of the biggest hidden costs in any industrial operation is absenteeism. When people are out with pain or injury, productivity grinds to a halt. Musculoskeletal disorders (MSDs), like chronic back pain and joint issues, are a primary reason for missed workdays, directly aggravated by standing on hard concrete.

By introducing a cushioned surface, industrial anti-fatigue mats dramatically reduce this physical strain. This proactive step helps slash the frequency of MSDs, lowering your risk of expensive workers' compensation claims. The direct benefit to you is fewer injuries, lower insurance premiums, and a more reliable team.

The real cost of an unsupported worker isn't just their salary. It's the lost productivity, overtime paid to cover their shift, and thousands in potential workers' compensation costs. Think of ergonomic matting as an effective insurance policy against those expenses.

This strategic shift is reflected in market trends. The global market for industrial anti-fatigue mats was valued at USD 1.80 billion in 2024 and is expected to climb to USD 3.09 billion by 2034. This growth is driven by companies recognizing the financial upside of investing in ergonomics. You can dive deeper into this trend with detailed market research from Precedence Research about anti-fatigue mat demand.

Boosting Productivity and Output

A comfortable worker is a focused and productive worker. When an employee isn’t distracted by aching feet or a sore back, they can put all their energy into the task at hand. This improved focus leads directly to better quality control, fewer mistakes, and a quicker work pace. The micro-movements the mats encourage also keep blood flowing, fighting off the mental fog that creeps in during a long shift.

-

Real-World Example of ROI:

A large distribution center tracked its performance before and after installing high-quality industrial anti-fatigue mats. After just six months, they achieved:

- A 20% reduction in reported safety incidents, including slips and strains.

- A measurable increase in line speed and units processed per hour.

- A significant drop in requests for unscheduled breaks due to physical discomfort.

This is proof of the direct line connecting ergonomic support to operational output. The investment in matting wasn't a cost center—it was a profit driver. By creating a safer, more comfortable workspace, the facility empowered its team to work at their best, delivering a clear return on investment.

How to Install and Maintain Mats for Maximum Lifespan

Investing in high-quality industrial anti fatigue mats is a brilliant first step, but their value is only unlocked with proper installation and consistent care. A poorly placed or neglected mat doesn't just fail to do its job—it can become a safety risk and lose its ergonomic benefits. This guide provides practical steps to ensure your mats perform at their best and last as long as possible.

Step-by-Step Installation for Immediate Safety

Getting the installation right is critical. Following these simple steps ensures your mats are safe and effective from day one.

- Clear the Area: Start by removing everything from the workstation floor.

- Thoroughly Clean and Dry: Sweep and then mop the floor with a suitable cleaner. Crucially, let it air dry completely. Trapping moisture underneath is a big no-no.

- Position the Mat: Lay the mat in its designated spot, ensuring it lies perfectly flat against the floor. Double-check that any beveled edges are sitting flush to prevent them from becoming a trip hazard.

- Secure if Necessary: On slick surfaces like coated concrete or epoxy, use non-slip adhesive strips or mat grips. This stops any potential movement in high-traffic zones.

Actionable Takeaway: A mat that slides is worse than no mat at all. Ensuring it stays put is the single most important part of preventing slips and falls and guaranteeing its ergonomic effectiveness.

A Practical Cleaning and Maintenance Protocol

Regular maintenance is non-negotiable if you want to extend the life of your matting. A simple, consistent routine is all it takes to prevent the material from breaking down and keep safety standards high.

- Real-World Example: In a busy fabrication shop, metal shavings and coolant are a daily reality. The end-of-day protocol is simple: sweep the mats and wipe them down with a pH-neutral cleaner. This prevents abrasive shavings from grinding into the surface and stops coolant from chemically degrading the mat material, directly extending the mat's lifespan and ensuring its safety.

Your cleaning method should always match the mat’s material:

- Rubber Mats: Use a mild, pH-neutral detergent. For stubborn grime, a deck brush works wonders. Avoid harsh, solvent-based cleaners.

- PVC/Vinyl Mats: These can usually be mopped with standard commercial floor cleaners. Just avoid aggressive degreasers, which can make the vinyl brittle.

- Polyurethane Mats: Often the easiest to care for. A simple wipe-down with a damp cloth is usually all that’s needed.

Knowing When to Replace Your Mats

Even the toughest industrial anti fatigue mats won't last forever. Regular visual inspections are crucial. Get into the habit of running through this simple checklist weekly:

- Check the Edges: Are they starting to curl up, crack, or lift away from the floor? Curled edges are one of the most common trip hazards.

- Inspect the Surface: Look for any tears, rips, or holes. These can easily catch a foot and collect debris.

- Test the Cushioning: Press down firmly on the areas that get the most use. Does it feel flat and compressed? If the mat doesn't spring back, its ergonomic benefit is gone.

Understanding when a mat is past its prime is just as important for safety as the initial installation. To get a better sense of what to expect, check out our guide on how long anti-fatigue mats last and the key signs of wear. Replacing a worn-out mat isn't a failure—it's a critical part of maintaining a safe and productive workplace.

Common Questions About Industrial Anti Fatigue Mats

Getting straight answers to common questions is crucial, because the right mat is an investment in your team's safety and your facility's productivity. Let's tackle the most common queries from facility managers.

How Thick Should an Industrial Mat Be?

While it's tempting to think thicker is better, that's not always the case. For most industrial jobs, the sweet spot for thickness is 5/8-inch. This measurement strikes the perfect balance between supportive cushioning and a firm, stable surface. If a mat is too thick or soft, it can backfire, forcing leg muscles to overcorrect and ironically making fatigue worse. For workstations with extremely long standing periods or for heavier team members, stepping up to a 7/8-inch mat can provide the necessary extra support.

Can I Use a Commercial Mat in an Industrial Area?

The answer is a hard no. You should never use a commercial or office mat in a true industrial setting. This is a common but dangerous mistake. Industrial mats are engineered with rugged materials like nitrile rubber or high-density polyurethane for a reason—they're built to survive harsh conditions. A standard commercial mat will break down quickly when exposed to industrial chemicals, oils, or heavy traffic, losing its ergonomic value and becoming a serious trip hazard as its edges curl and the surface disintegrates.

When Do I Need to Replace My Anti Fatigue Mat?

An industrial mat’s lifespan is typically one to three years, but this varies based on traffic and environment. You must replace it at the first visible signs of significant wear.

Actionable Insight: A worn-out mat is a safety liability, not an asset. Once the cushioning is gone and the edges are compromised, it no longer provides ergonomic support and actively creates new trip hazards.

Make regular inspections part of your routine. Be on the lookout for these tell-tale signs:

- Curled Edges: The edges are lifting and no longer lie flat.

- Cracks or Tears: You can see any physical damage or splits on the surface.

- Flattened Cushioning: Certain areas feel compressed and have lost their bounce-back.

Understanding the full scope of anti-fatigue mat benefits really drives home why keeping them in top condition is so important. In places like North America, strict occupational safety regulations further underscore the need for effective ergonomic solutions to cut down on musculoskeletal issues. You can learn more about the high adoption rates in industrial sectors and the standards pushing this trend forward.

Ready to create a safer, more productive environment? The experts at Mats4U can help you select the perfect industrial anti fatigue mats for your facility's unique needs. Explore our extensive collection of high-performance matting solutions today.